belt driven hammer mill

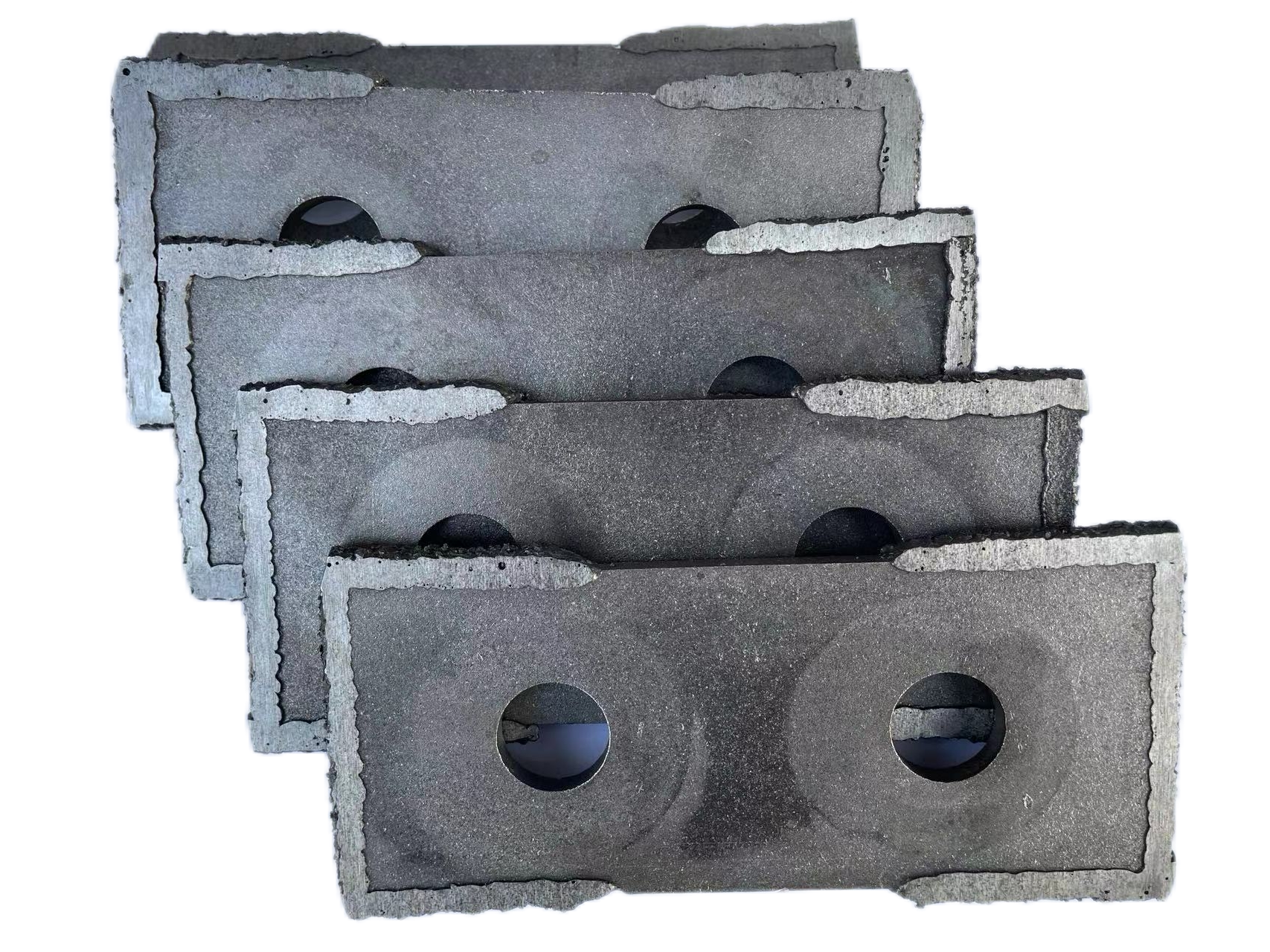

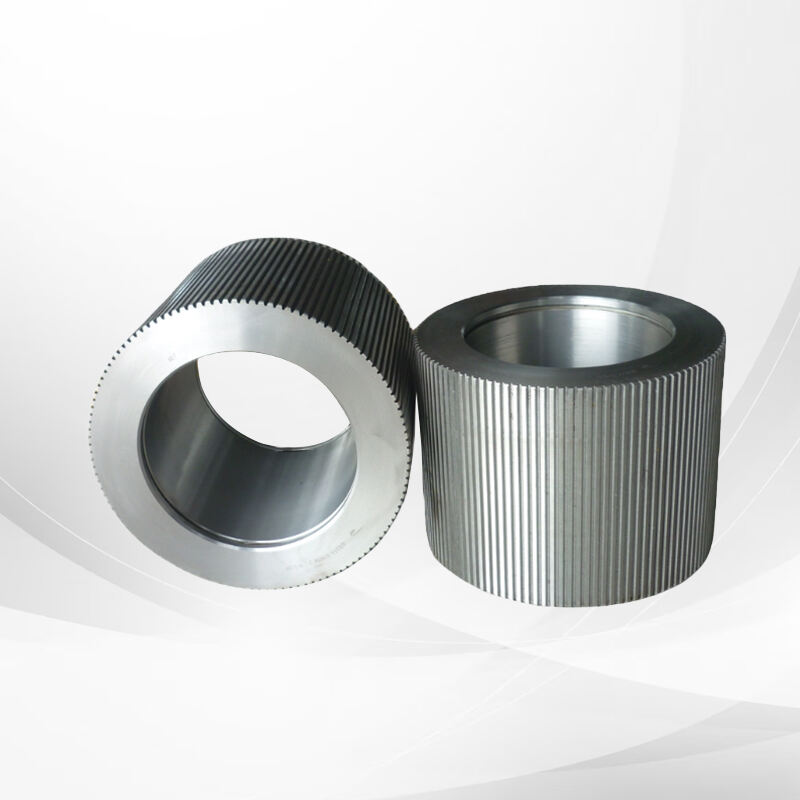

The belt driven hammer mill represents a cornerstone in material processing technology, combining robust engineering with efficient operation principles. This versatile machine utilizes a belt drive system to power a series of rotating hammers that effectively reduce materials to desired particle sizes. At its core, the hammer mill consists of a rotor assembly mounted with multiple hammers that swing freely, creating a high-impact crushing action when materials enter the grinding chamber. The belt drive system transfers power from the motor to the rotor shaft, ensuring smooth operation and consistent performance. The machine's design incorporates a carefully engineered screen that controls the final product size, allowing only properly reduced particles to pass through. This system proves particularly effective in processing various materials, including grains, minerals, and agricultural products. The hammer mill's grinding chamber features replaceable liner plates that protect the housing from wear while enhancing grinding efficiency. Advanced safety features include emergency stop mechanisms and overload protection systems, ensuring operator safety and equipment longevity. The machine's modular design facilitates easy maintenance and part replacement, minimizing downtime and operational costs. With applications spanning across multiple industries, from agriculture to mining, the belt driven hammer mill delivers reliable performance and consistent output quality.