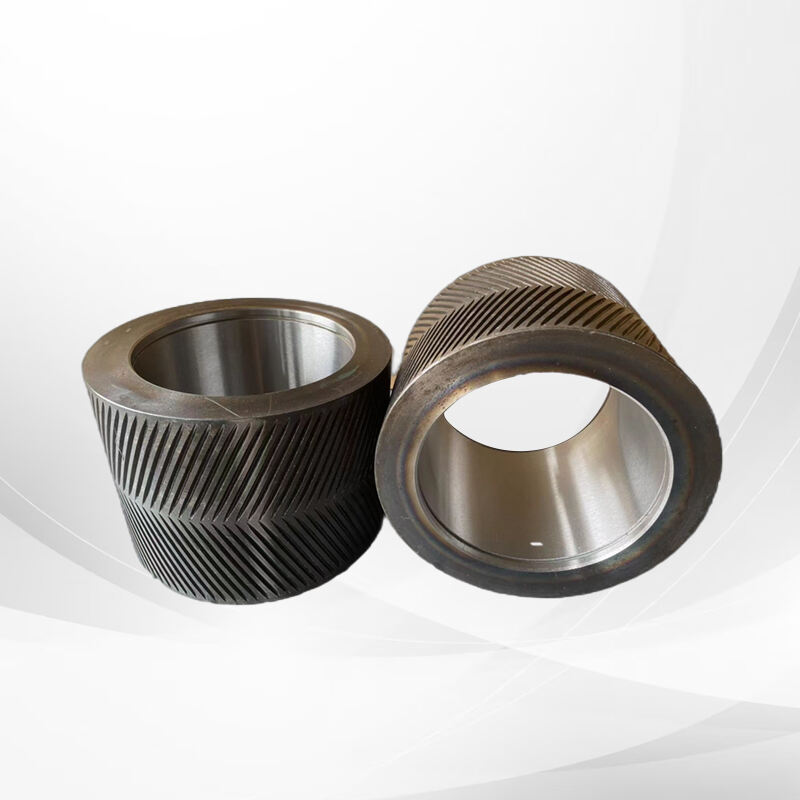

mlinska šiljka češlji

Ostrik za cepur je ključni deo u industrijskom mašinstvu za drvećanje i smanjenje veličine materijala, dizajniran da efikasno procesira različite materijale u manje, uniformne čestice. Ovi specijalizovani ostrikovi, obično izrađeni od visokokvalitetne otopljive ocele ili otpornih legura, rade unutar rotirajuće konstrukcije cepura. Dok rotor rotira na visokoj brzini, ostrikovi stvaraju moćne udarne snage koje drpe, šure i drmljaju materijale protiv rešetke ili drmačke ploče. Dizajn ostrika uključuje precizne uglove i sečne ivice koje optimiziraju smanjenje materijala prilikom održavanja operativne efikasnosti. Savremeni ostrikovi za cepur koriste napredne metalurgijske sastave koji poboljšavaju otpornost i otpornoću, čak i prilikom obrade abrazivnih materijala. Ti ostrikovi su neophodni u industrijama poput poljoprivrede, rudarstva, reciklaže i obrade hrane, gde obavlja zadatke od drvećanja zrna do smanjenja metalkog otpada. Konfiguracija ostrika može biti prilagođena na osnovu specifičnih zahteva primene, sa opcijama za različite debljine, oblike i montažne raspoređivanja kako bi se postigla optimalna performansa i dugotrajnost.