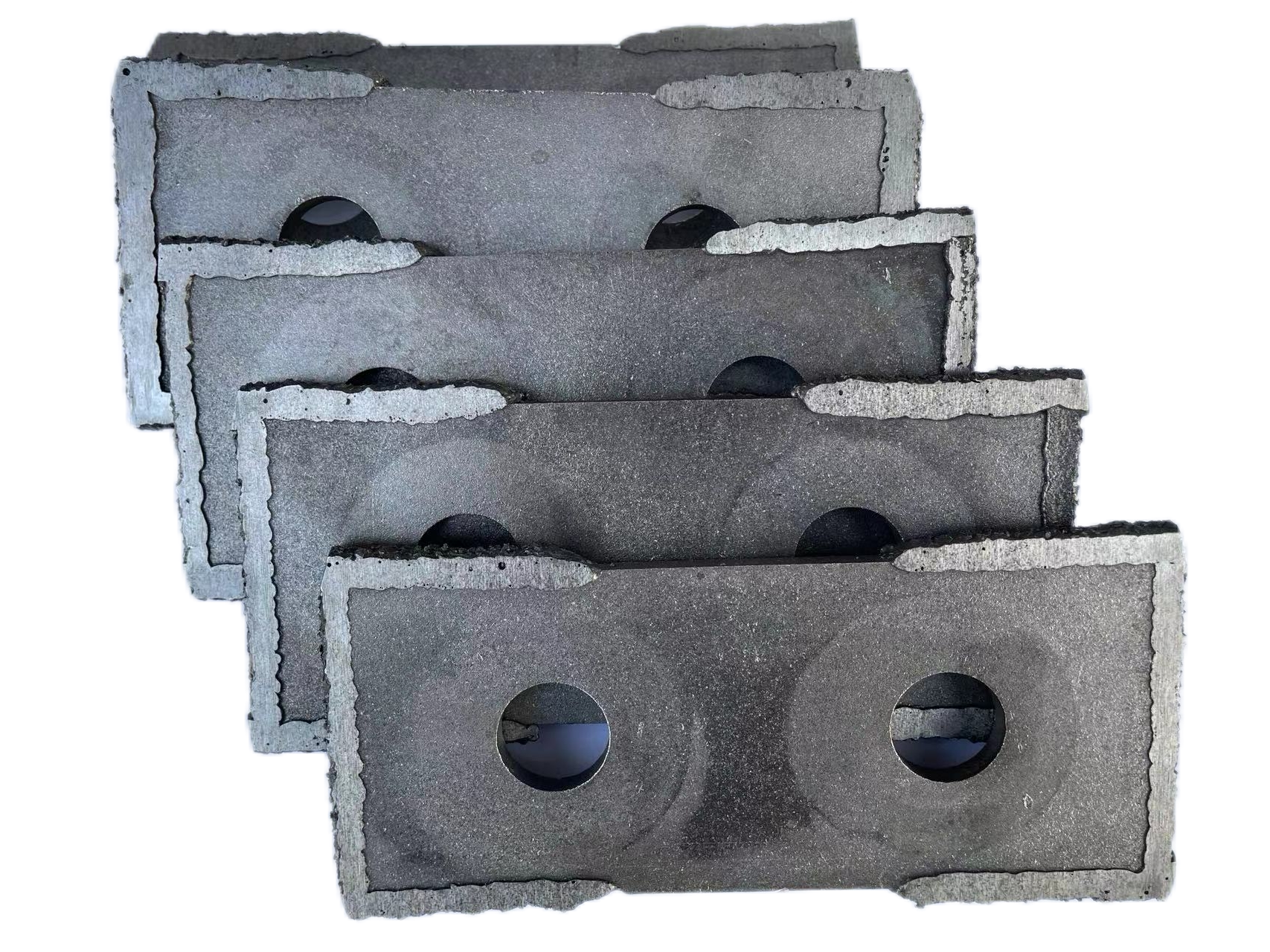

nýjustu útfærslu hamarskjárarbláið

Nýjastaðall útgáfa af hrykkjubíta hammer millinn framkvæmir mikilvægum framskridi í þéttunartækni, með því að innföra fremst áframstöðuverkfræðilegar reglur til að birta yfirleitt virkni og nákvæmni. Þessi nýskapandi bíta hefur nákvæmlega ræst skurðargreni sem eru gerðir af háhagleiku, mótskeytingarfastu járnstali, sérstaklega útfærð til að standa við inntaka grindarkerfi meðan þeir halda við bestu skarpni. Bíturnar einstakt geimskipun inniheldur stefnd skurðarsvæði sem auka smásælu nákvæmni samtidlega sem þeir minnka dreifingu af orku. Framúrskurðin ræstur inniheldur bætt aerodynamics, með því að draga fyrir neðan efriþolustu og tryggja samfelld stærð á partiklum. Styrktin fastanleiki bíturnar kemur frá sérstoku hitaverkforritu sem lengkar þeirra starfsaldrann mikilvægt lengra en venjulegri útgáfur. Þessar bítur eru sérstaklega gagnslegar við að vinna mörg tegundir af efnum, þar á meðal korn, steinar og líffjölskyldu efni, með undirstöðu samfelldni. Útgáfan hefur nýskapandi tengiskerfi sem leyfir fljótt umbreytingu og stillingu, minnkandi tíma fyrir viðhald. Auk þess, jafnvægið á bíturnar minnkar hrifar á keyrslu, bætir sömukeyrslu og lækkar mótskeytingu á milliþéttunarhluta. Nýjust útgáfa er samhæfd með flestum nútímalegum hammer mill kerfum og getur verið síðgreind til að uppfylla sérstök þéttunarkröfur.