cijena vrtljičkog mlinskega stroja

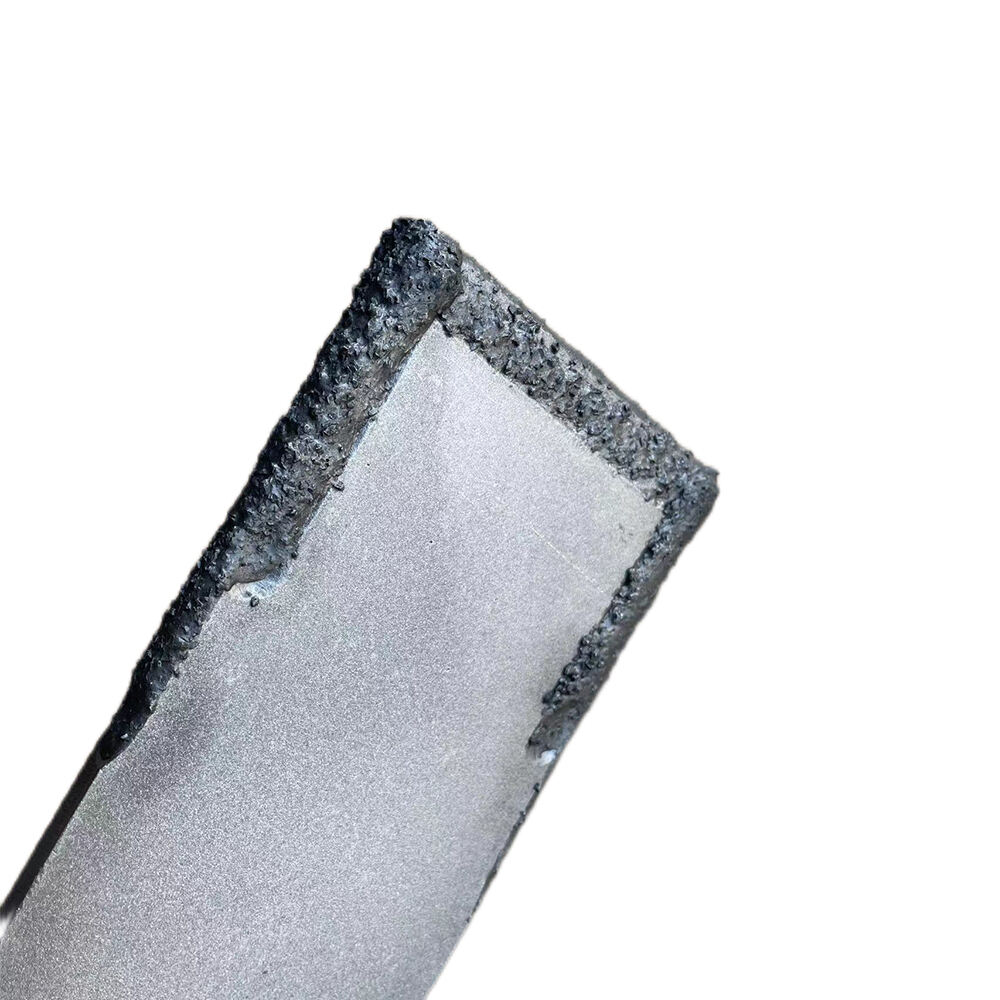

Cijena klinčane mlinice predstavlja ključnu razmatranju za poduzeća koja traže učinkove rješenja za obradu materijala. Ova fleksibilna oprema, dizajnirana za smanjenje veličine i obradu čestica, nudi izuzetnu vrijednost kroz svoju čvrstu konstrukciju i pouzdanu performansu. Suvremene klinčane mlinice uključuju napredne značajke poput prilagodljivih brzina rotora, precizno inženiranih klinova i sofisticiranih upravljačkih sustava, što omogućuje optimalnu učinkovitost obrade različitih materijala. Struktura cijene obično odražava faktore kao što su kapacitet obrade, snaga motora, kvaliteta građe i dodatne značajke poput automatskih sustava za hrpačenje ili mehanizama za skupljanje prašine. Kada se procjenjuju cijene klinčanih mlinica, važno je uzeti u obzir kapacitet stroja, koji može raspršavati od maloprodavnih operacija koje obrađuju nekoliko tona po satu do industrijskih jedinica koje obrađuju stotine tona dnevno. Početni ulog obuhvaća ne samo osnovnu jedinicu, već i opcije prilagođavanja, sigurnosne značajke i potencijalne mogućnosti automatizacije. Proizvođači često nude različite cijene na temelju materijala građe, s opcijama od standardne ocele do otpornih legure za obradu iznosivih materijala. Cijena također uzima u obzir sofisticiranost upravljačkog sustava, od osnovnih ručnih upravljanja do naprednih PLC sustava s mogućnošću udaljene nadzorivanja. Razumijevanje ovih komponenti pomaže poduzećima donijeti obrazbano odluke o investiciji u tehnologiju klinčanih mlinica.