цена на малка машина за плочки

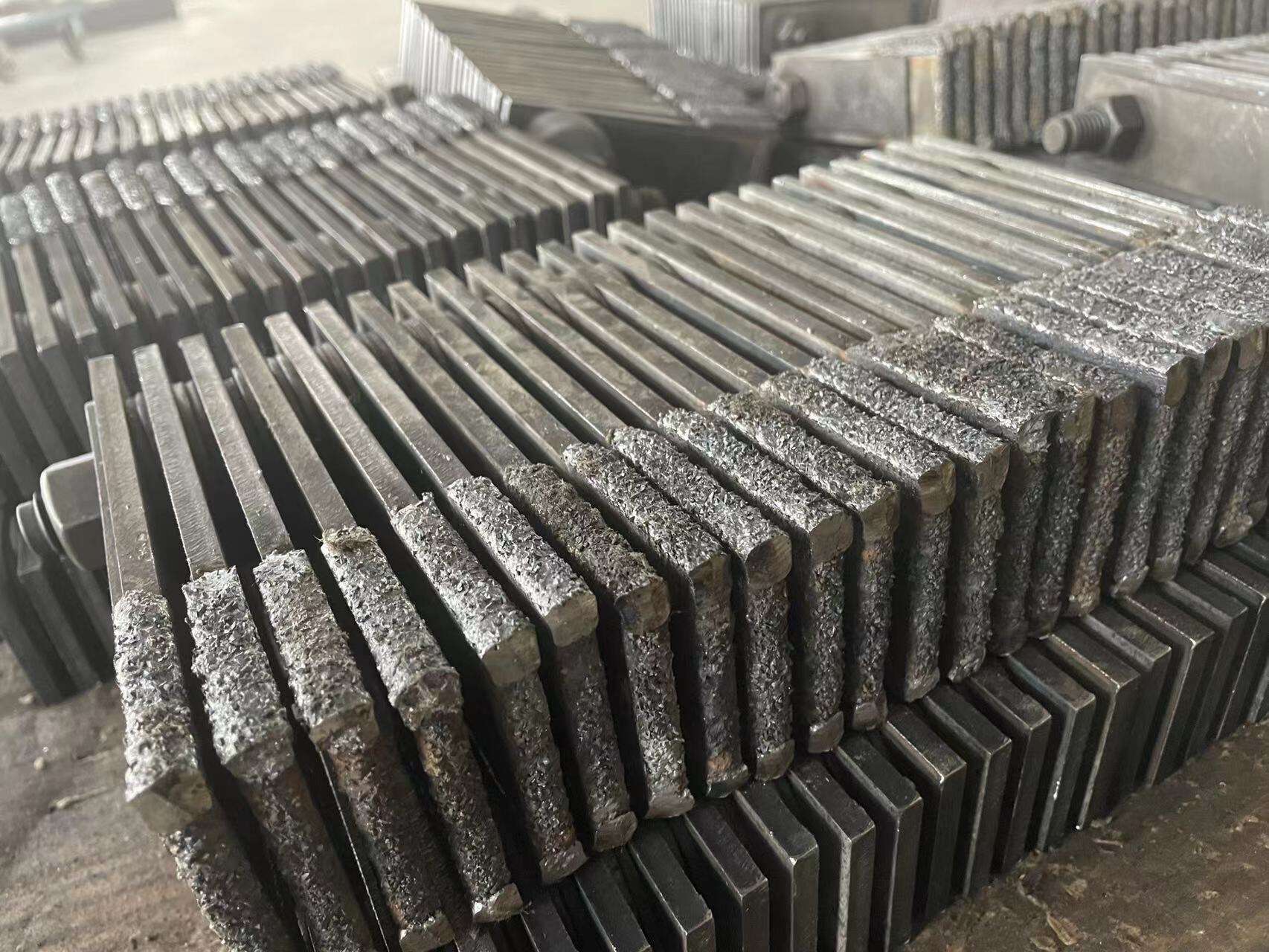

Цената на малките пелетни машини е значителен фактор за бизнесите и индивидите, които искат да се включат в производството на пелети. Тези компактни машини, чиято цена обикновено се намира между 800 и 3000 долара, предлагат достъпна врата за влизане в производството на пелети. Модерните малки пелетни машини комбинират ефективност с доступност, разполагайки с точно проектираните си компоненти, които гарантират последователно качество на пелетите. Единиците обикновено обработват от 50 до 200 кг на час, което ги прави идеални за малко и средно мащабни операции. Те включват moden технология на матрица и ролкери, която позволява обработка на различни материали, включително биомаса, храна и дърво. Цената често отразява качеството на конструкцията на машината, мощността на мотора и производственият капацитет. Повечето модели разполагат с регулируемо давление на матрицата, контрол на променливата скорост и сигурносни механизми. Тези машини са проектирани за лесно техническо обслужване и управление, с заменими изнасящи се части, които помогnat за продължаване на живота на машината. Инвестицията обикновено включва основни аксесоари като матрични форми, ролкери и основни инструменти за техническо обслужване, което осигурява пълен стойностен потенциал за първоначалната цена.