İrəliləmiş dələn texnologiyası ilə sənaye emalı performansını artırmaq

Sənaye emalının dinamik dünyasında dələn bıçaqları material azaltma texnologiyasının ön sırlarında yer alır. Bu vacib komponentlər sənaye tətbiqlərində xüsusilə dağınma, əzilmə və hissəcik ölçüsünün azaldılması ilə bağlı proseslərə yanaşmanı dəyişdirir. Kənd təsərrüfatı emalından təkrar emal operasiyalarına qədər, döyüşülən dəliklərin iş prosesinin səmərəliliyi və məhsul keyfiyyətinə təsiri böyük əhəmiyyət kəsb edir. Onların əhəmiyyətini başa düşmək, obyektlərin rəhbərləri və emal sahəsində çalışan mütəxəssislər üçün işlərini optimallaşdırmaq üçün vacibdir.

Döyücü dəliyin konstruksiyası və tikintisinin başa düşülməsi

Material Tərkibi və Davamlılıq Xüsusiyyətləri

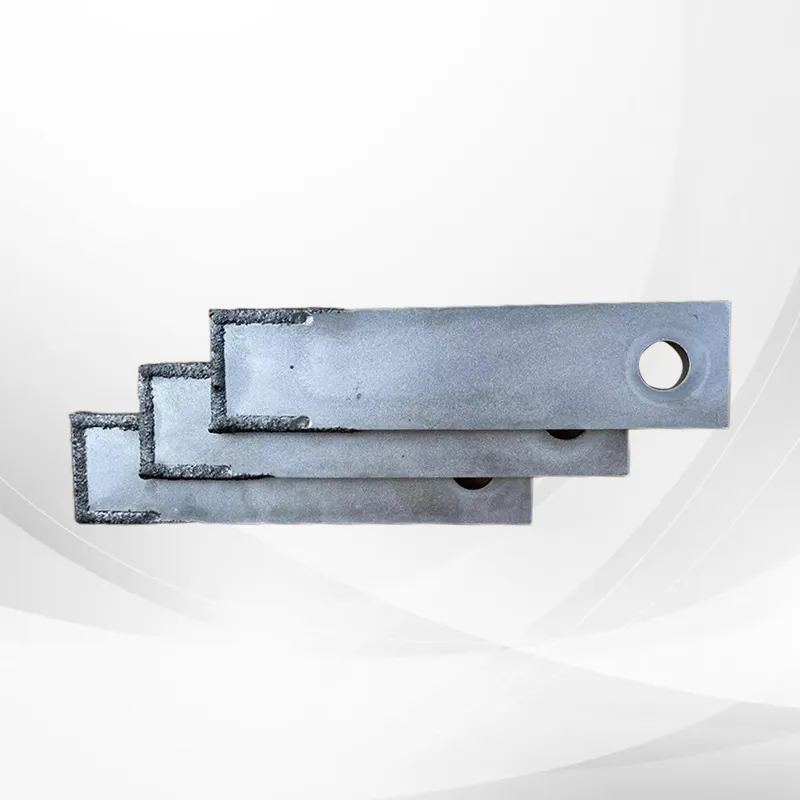

Dələnmiş dəmirin bıçaqlarının səmərəliliyi onların konstruksiya materialları ilə başlayır. Yüksək keyfiyyətli ərinti poladı, adətən sərtləşdirilmiş və temperlənmiş, keyfiyyətli bıçaqların əsasını təşkil edir. Bu materiallar optimal sərtlik və möhkəmlik balansını əldə etmək üçün dəqiq istilik emalı proseslərindən keçir. Müasir dələnmiş dəmir bıçaqları tez-tez xidmət ömrünü uzatmaq və tələb olunanan şərtlərdə davamlı performans saxlamaq üçün xətti müqavimətli örtüklər və xüsusi kənar emalı əlavə edir.

İrəli metallurgiya texnikaları ümumi xərdələnmə nümunələrini və sıradan çıxma nöqtələrini hədəf alan yeni ərinti kombinasiyaları təqdim etmişdir. Bu innovasiyalar dələnmiş dəmir bıçaqlarının güclü təsir qüvvələrinə davam gətirməsinə və kəsmə kənar bütövlüyünü saxlamasına imkan verir. Materialların diqqətli seçilməsi yalnız bıçağın xidmət ömrünü, həmçinin istismar müddəti ərzində eyni hissəcik ölçüsünü saxlamaq qabiliyyətini təsir edir.

Optimal Performans Üçün Həndəsi Konfiqurasiyalar

Dələn pərələrinin dəzgah həndələri onların effektivliyində mühüm rol oynayır. Müxtəlif tətbiqlər müəyyən pərə profillərini tələb edir: lifli materiallar üçün düz kənarlı konfiqurasiyalar, qruntlu maddələr üçün isə əyri dizaynlar. Hücum bucağı, pərə qalınlığı və quraşdırma yeri hamısı materialların effektiv şəkildə emalını təmin edərkən enerji sərfiyyatını minimuma endirməyə kömək edir.

Müasir dələn pərələri dəqiqliklə hazırlanmış kəsici kənarlara və çəki paylanmasının nəzərdə tutulmuş hesablamalarına malikdir. Bu dizayn elementləri bərabər aşınma nümunələrini təmin edir və yüksək sürətli iş zamanı düzgün balans saxlamağa kömək edir. Pərə həndələsi ilə rotor dizaynı arasındakı əlaqə təyin olunmuş hissəcik ölçüsünü əldə etmək və avadanlıq üzərində artıq gərginliyi qarşısını almaq üçün optimallaşdırılmalıdır.

Ən yüksək effektivliyə çatmaq üçün operativ hesabatlara baxın

Sürət və Verilmə Dərəcəsinin Optimallaşdırılması

Dələn bıçaqları ilə materialın verilmə sürəti arasındakı qarşılıqlı təsir diqqətli kalibrlənmə tələb edir. İşləmə parametrləri materialın xarakterinə, istənilən çıxış ölçüsünə və avadanlıq spesifikasiyalarına əsasən tənzimlənməlidir. Uyğun sürət parametrlərinin təyini dələn bıçaqlarının optimal təsir gücünü saxlamasını təmin edərkən avadanlığın aşırı yüklənməsi və ya səmərəsiz işlənməsini qarşısını alır.

Materialın verilmə sürətinin idarəetmə sistemi bıçaqların dizaynı ilə birlikdə işləyərək nəticələrin sabitliyini təmin edir. İrəliləmiş monitorinq texnologiyaları operatorlara buraxılış həcmi ilə hissəciklərin ölçüsünün paylanması arasındakı ideal balansı saxlamağa kömək edir. Materialın verilmə sürəti ilə bıçaqların işləməsi arasındakı bu sinxronizasiya səmərəliliyi artırır və kritik komponentlərdə aşınmanı minimuma endirir.

Təmir Qaydaları və Məhsuldarlığın Monitorinqi

Döyən dənələrin bıçaqlarının müntəzəm yoxlanılması və təmiri davamlı performans üçün vacibdir. Optimal fırlanma və ya əvəzetmə cədvəlini müəyyən etmək üçün aşınma nümunələrini izləmək lazımdır. Proqnozlaşdırıcı təmir strategiyalarının həyata keçirilməsi gözlənilmədən dayanmanı qarşısını alır və məhsul keyfiyyətinin sabitliyini təmin edir.

Bıçaq performansı metrikalarının sənədləşdirilməsi operatorlara meylləri müəyyən etməyə və əvəzetmə intervallarını optimallaşdırmağa imkan verir. Bu məlumatlara əsaslanan təmir yanaşması istehsalat sahələrinə operativ xərclərlə məhsuldarlıq məqsədləri arasında balans yaratmağa kömək edir. Müntəzəm bıçaq təmiri həmçinin aşınmış komponentlərlə əlaqəli artan enerji istehlakını qarşısını alaraq enerji səmərəliliyinə də töhfə verir.

İrəli Düzəliş Tətbiqləri və Sənaye Tendensiyaları

Xüsusi Emal Sahəsində İnkişaf

Dələn bıçaq texnologiyasında son inkişaflar onların müxtəlif sənayelərdə tətbiqini genişləndirib. Yeni bıçaq dizaynları dərman vasitələrinin emalı, tullantıların təkrar emalı və biomüxtəlifliyin azaldılması ilə bağlı xüsusi problemləri həll edir. Bu kimi xüsusi tətbiqlər tez-tez dəqiq hissəcik ölçülərinin təyini və emal səmərəliliyinin saxlanması üçün fərdi bıçaq konfiqurasiyaları tələb edir.

Ağıllı istehsal prinsiplərinin inteqrasiyası nəticəsində dələn bıçaqlarında sensorlar və monitorinq imkanları mövcuddur. Bu innovasiyalar real vaxtda məhsuldarlığın izlənilməsinə və proqnozlaşdırıcı təmirə imkan verir və bu da materialların emal texnologiyasının gələcəyini əks etdirir. Sənaye sahələrinin daha dəqiq və səmərəli azaltma üsullarına olan tələbləri davam etdikcə bıçaqların dizaynında inkişaf texnoloji irəliləyişin ön saflarında qalmaqdadır.

Yenilenebilirlik və Çevrə Təsiri

Müasir döyüş sınaqlarının millərinin yaxşılaşdırılması enerji səmərəliliyinin artırılması və tullantıların azalmasında müstəsna rol oynayır. Yaxşılaşdırılmış sınaq dizaynı güc istehlakını azaldır və emal effektivliyini saxlayır. Təkrar emal olunan və uzunömürlü materialların hazırlanması sənaye təşkilatlarının ətraf mühit məsuliyyəti sahəsindəki məqsədlərinə uyğundur.

Döyüş sınaqlarının tullantıların emalında oynadığı rol genişlənməkdə davam edir, yeni dizaynlar müxtəlif tullantı materiallarının emalı üçün nəzərdə tutulmuşdur. Bu tətbiqlər texnologiyaların tullantıların dövri emalı təşəbbüslərinə və davamlı istehsal praktikalarına dəstək verdiyini göstərir.

TEZ TEZ VERİLƏN SORĞULAR

Döyülmə Bıçaqları Nə qədər Tezliklə Dəyişdirilməlidir?

Əvəzetmə intervalı emal olunan materialdan, iş şərtlərindən və bıçaq dizaynından asılıdır. Ümumiyyətlə, sənaye müəssisələri bıçaqları həftəlik yoxlamalı və istehsalçının spesifikasiyalarından artıq aşınma baş verdikdə və ya emal effektivliyi kəskin azaldıqda əvəzetmək üçün planlaşdırmalıdır. Əksər müəssisələr bıçaqları 3-6 ayda bir dəfə əvəz edir, lakin bu müddət istifadə nümunələrindən asılı olaraq əhəmiyyətli dərəcədə fərqlənə bilər.

Döyüş dələli bıçaqlarının seçilməsinə hansı amillər təsir edir?

Əsas diqqət yetirilməli məsələlər emal olunan materialın növü, istənilən hissəcik ölçüsü, buraxılış tələbləri və iş mühitini özündə birləşdirir. Materialın sərtliyi, rütubətliyi və aşındırıcı təsiri bıçaqların seçilməsində mühüm rol oynayır. Bundan əlavə, elektrik təchizatı və təmir imkanları kimi obyektə xas amillər də bıçaq dizaynı və materialının seçimini təsir altına almalıdır.

Operatorlar döyüş dələli bıçaqlarının xidmət müddətini necə artırabilir?

Dəyirmi ömrünü uzatmaq üçün operatorlar düzgün verilmə sürətini saxlamalı, rotorun düzgün sürətini təmin etməli və müntəzəm təmizləmə protokollarını həyata keçirməlidirlər. Düzgün ekranlama sistemlərinin və metal aşkarlama avadanlığının quraşdırılması tramp materiallardan qorunmağa kömək edir. Düzgün komponentlər arasındakı boşluqların saxlanması və dəyirmi dəfələrinin müntəzəm dəyişdirilməsi də dəyirmi ömrünün optimal uzunluğuna kömək edir.